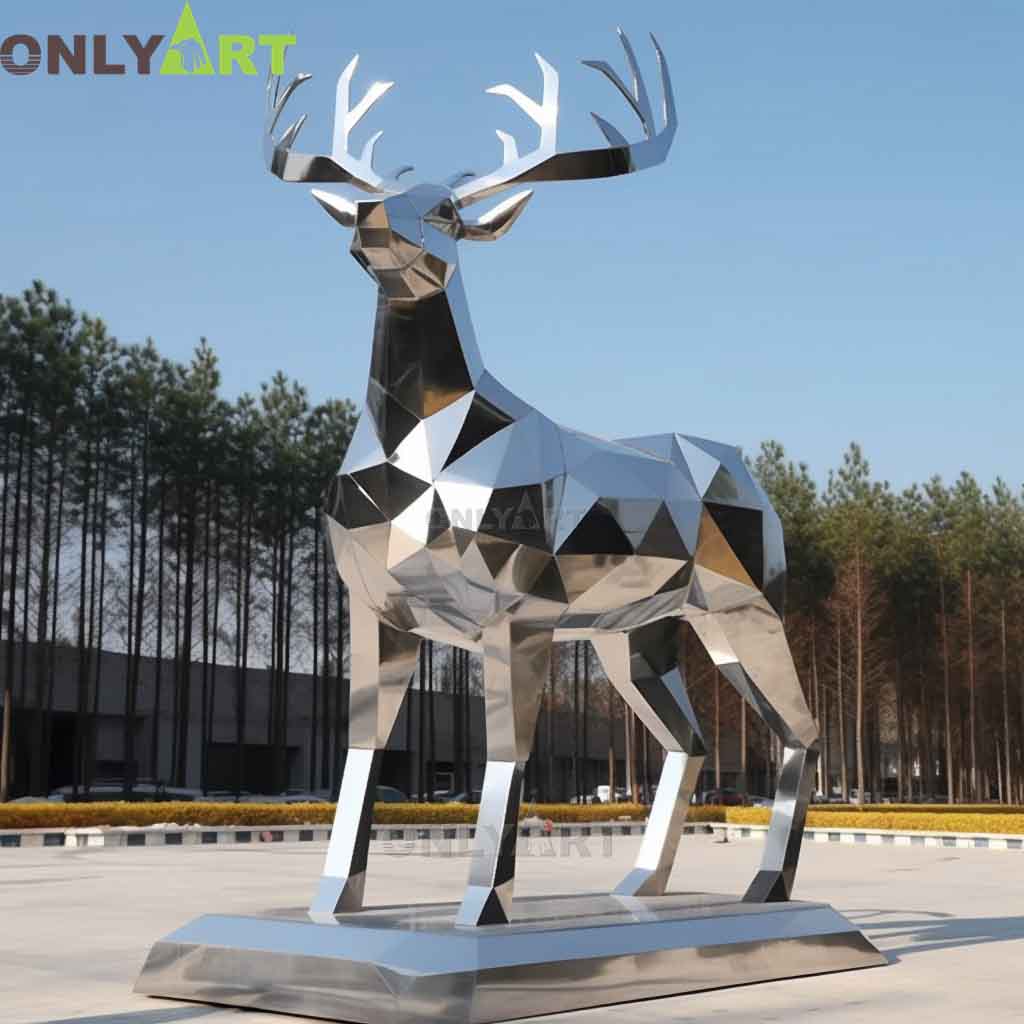

Latest Custom Project Sculptures

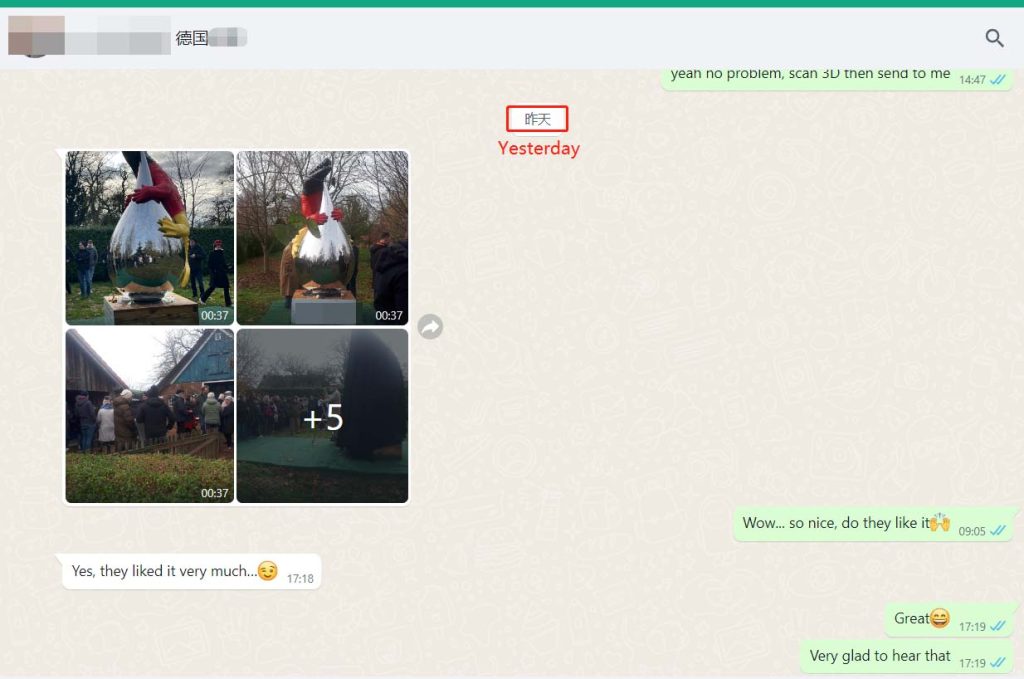

1. Discuss with customers the specific pictures of metal stainless steel sculptures and the theme and style of metal sculptures to determine the preliminary design direction.

2. Sketches and design drawings of the sculptures, our 3D modeling team makes 3D drawings or sketches to create detailed design drawings.

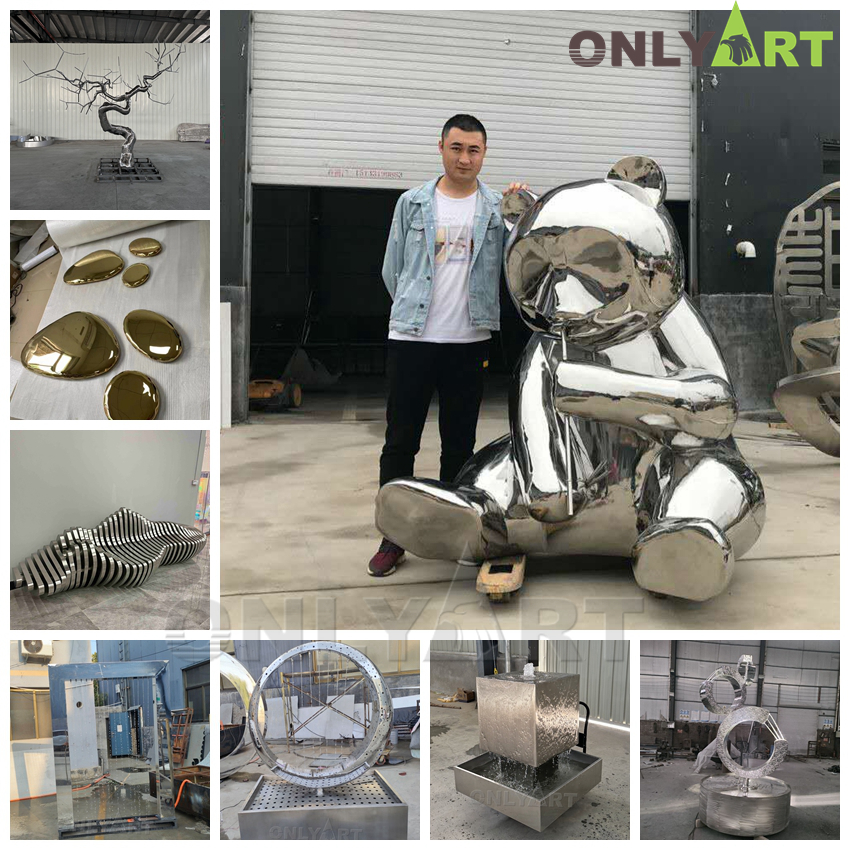

3. After receiving the 3D drawings confirmed by the customer, our Onlyart Sculpture Factory uses laser cutting, plasma cutting or water jet cutting technology for precision cutting processing to cut the stainless steel material into the required shape and size.

4. Welding, we use laser welding or argon arc welding to weld and assemble the cut stainless steel sculpture pieces together, so that the general model outline of the stainless steel sculpture is revealed. Stainless steel metal sheets are prone to deformation during welding, but our Onlyart Sculpture Factory can solve this problem of welding deformation.

5. Grinding and polishing: Grind the welding parts and surfaces to remove welding marks and defects.

6. Install embedded parts at the bottom of the sculpture. Sometimes customers put the stainless steel sculpture directly on the ground, so there is no need to install embedded parts at the bottom of the sculpture. Many customers need to weld it to the cement floor, so we need to make embedded parts.

7.Such stainless steel sculptures are ready-made from conception to finished product.

Stainless steel sculptures are generally packed with soft waterproof foam and blanket inside, and packed with sturdy wooden boxes outside, specially for sea freight export, just ready to arrive at your seaport.

Small sculptures or life-size sculptures can be shipped by air or train in fumigation-free full-cover boxes, any courier is OK, such as DHL, TNT, UPS or FedEx, door-to-door delivery, about 8-10 days can arrive directly at your door.

Large sculptures will use special iron boxes, if you want custom packaging, please contact OnlyArt Sculptures.

you may also like

Tell Us About Your Specific Needs For Custom Sculpture!

Error: Contact form not found.